Various Applications and Uses of 3D Laser Scanning in Construction

In the field of construction, technological advancements have revolutionized traditional methods and introduced innovative tools that enhance efficiency and accuracy.

One such ground-breaking technology is 3D laser scanning, which has gained significant popularity due to its wide range of applications and uses.

This article explores the various ways in which 3D laser scanning is employed in the construction industry, revolutionizing the surveying process and enabling better project management.

Laser Survey

Let us discuss first what is a Laser Survey.

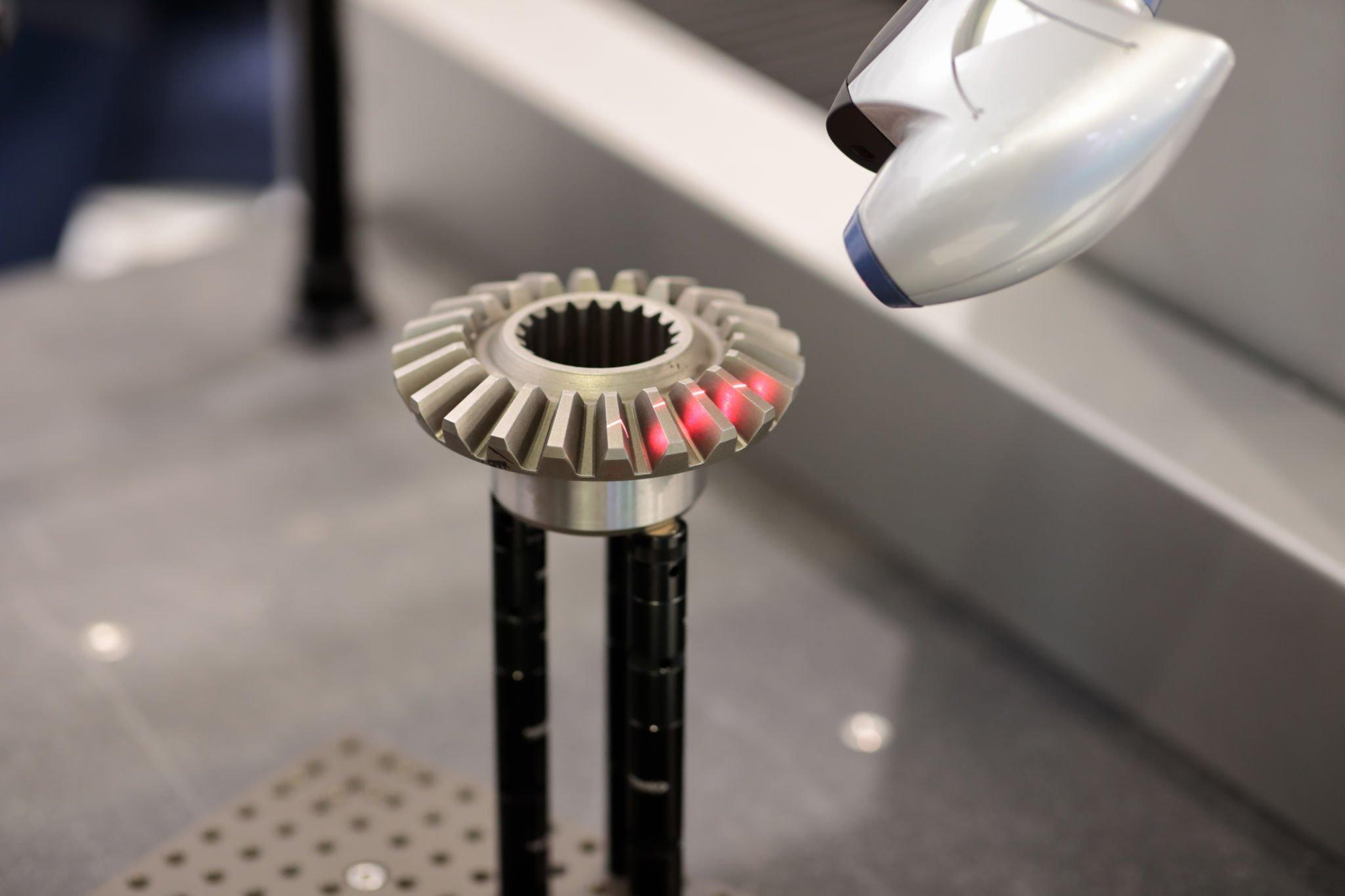

A laser survey, also known as 3D laser scanning or LiDAR (Light Detection and Ranging), is a non-intrusive method used for the following purposes:

- To capture precise measurements

- To collect detailed data on existing structures, objects, or environments.

This technology utilizes laser beams to create a point cloud of millions of accurate measurements, forming a digital representation of the scanned area.

Preliminary Surveys and Documentation

3D laser scanning has proven to be an invaluable tool for conducting preliminary surveys and documentation in the construction industry.

It enables surveyors to capture accurate measurements of existing structures and landscapes, eliminating the need for manual measurements and reducing human errors.

This data can then be used for designing new structures or remodeling existing ones, ensuring precise planning and minimizing project risks.

Read also: Important Elements and Types of Search Engine Optimization

Construction Monitoring and Quality Control

During the construction phase, 3D laser scanning allows for real-time monitoring and quality control.

By periodically scanning the construction site, project managers can compare the as-built conditions with the original design, ensuring adherence to specifications and identifying any deviations.

This technology enables early detection of potential issues, thereby mitigating costly rework and delays.

Clash Detection and Coordination

Coordinating multiple disciplines in a construction project can be challenging. However, 3D laser scanning streamlines the coordination process by facilitating clash detection.

By overlaying various design models onto the point cloud data, engineers and architects can identify clashes or conflicts between different building systems,

such as:

- Mechanical

- Electrical

- Plumbing

This early detection of clashes helps in resolving issues before construction, saving time and resources.

As-Built Documentation and Facility Management

After the completion of a construction project, accurate as-built documentation is crucial for future maintenance and facility management.

3D laser scanning provides comprehensive and precise documentation of the final built environment, including intricate details and measurements.

This information can be utilized for asset management, space planning, renovations, and expansions, ensuring efficient facility maintenance throughout its lifecycle.

Historic Preservation and Restoration

3D laser scanning has also found applications in historic preservation and restoration projects. By capturing detailed measurements and digital representations of historical structures, this technology allows for accurate documentation and analysis of architectural elements.

It enables preservationists and architects to plan restoration work, replicate intricate details, and create virtual models for educational or research purposes.

Conclusion

3D laser scanning has revolutionized the construction industry by offering a multitude of applications and uses.

From preliminary surveys and construction monitoring to clash detection and historic preservation, this technology provides:

- Accurate and detailed data that enhances project efficiency

- Improves coordination, and reduces risks.

As construction projects become increasingly complex, 3D laser scanning continues to play a pivotal role in streamlining processes, ensuring quality control, and enabling better decision-making throughout the project lifecycle.

Average Rating